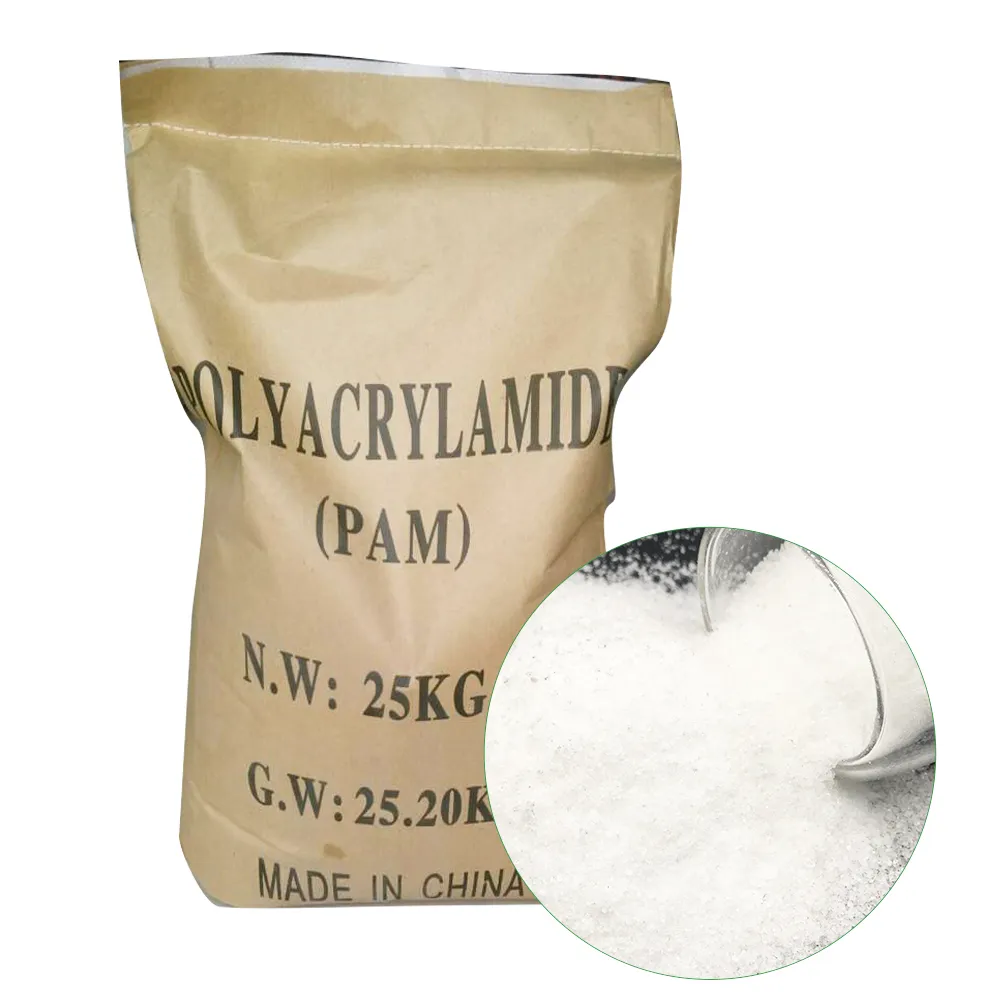

Polyacrylamide Molecular Water Treatment Chemicals

Polyacrylamide (PAM) is a general term for acrylamide homopolymer or copolymerized with other monomers, and is one of the most widely used varieties of water-soluble polymers. Because the structural unit of polyacrylamide contains amide groups, it is easy to form hydrogen bonds, which makes it have good water solubility and high chemical activity, and it is easy to obtain various modifications of branched chain or network structure through grafting or crosslinking. , It is widely used in petroleum exploration, water treatment, textile, papermaking, mineral processing, medicine, agriculture and other industries, and is known as "auxiliaries for all industries". The main application fields in foreign countries are water treatment, papermaking, mining, metallurgy, etc.; in China, the largest amount is currently used in the field of oil extraction, and the fastest growing fields are in the fields of water treatment and papermaking.

Water treatment field:

Water treatment includes raw water treatment, sewage treatment and industrial water treatment. Used in conjunction with activated carbon in raw water treatment, it can be used for coagulation and clarification of suspended particles in domestic water. The use of organic flocculant acrylamide instead of inorganic flocculant can increase the water purification capacity by more than 20% even without modifying the settling tank; in sewage treatment, the use of polyacrylamide can increase the utilization rate of water recycling and can also be used as Sludge dewatering; used as an important formulation agent in industrial water treatment. The largest field of application of polyacrylamide abroad is water treatment, and the application in this field in China is being promoted. The main role of polyacrylamide in water treatment: [2]

(1) Reduce the amount of flocculant. Under the premise of achieving the same water quality, polyacrylamide is used as a coagulant aid in combination with other flocculants, which can greatly reduce the amount of flocculant used; (2) Improve water quality. In drinking water treatment and industrial wastewater treatment, the use of polyacrylamide in combination with inorganic flocculants can significantly improve water quality; (3) Increase floc strength and sedimentation velocity. The flocs formed by polyacrylamide have high strength and good sedimentation performance, thereby increasing the solid-liquid separation speed and facilitating sludge dehydration; (4) Anti-corrosion and anti-scaling of the circulating cooling system. The use of polyacrylamide can greatly reduce the amount of inorganic flocculants, thereby avoiding the deposition of inorganic substances on the surface of equipment and slowing down the corrosion and scaling of equipment.

Polyacrylamide is widely used as retention aid, filter aid, leveling agent, etc. in the papermaking field to improve paper quality, slurry dehydration performance, retention rate of fine fibers and fillers, reduce raw material consumption and environmental pollution, Used as a dispersant to improve the uniformity of paper. Polyacrylamide is mainly used in two aspects in the paper industry. One is to increase the retention rate of fillers and pigments to reduce the loss of raw materials and environmental pollution; the other is to increase the strength of paper. Adding polyacrylamide to the paper material can increase the retention rate of fine fibers and filler particles on the net and accelerate the dehydration of the paper material. The mechanism of action of polyacrylamide is that the particles in the slurry are flocculated and retained on the filter cloth by neutralization or bridging. The formation of flocs can also make the water in the slurry easier to filter out, reducing the loss of fibers in white water, reducing environmental pollution, and helping to improve the efficiency of filtration and sedimentation equipment